Equipment

| Year of Installation | Equipment | Details |

|---|---|---|

| 2002 | 1 set of paper machine | 1 Line |

| 2002 | Making equipment | 1 Line |

| 2002 | Wastewater treatment plant | 2 kinds of water quality |

| 2008 | Waste incinerating boiler | City gas boiler 94.8 ton |

| 2008 | City gas boiler | Changed to gas boiler in 2008 |

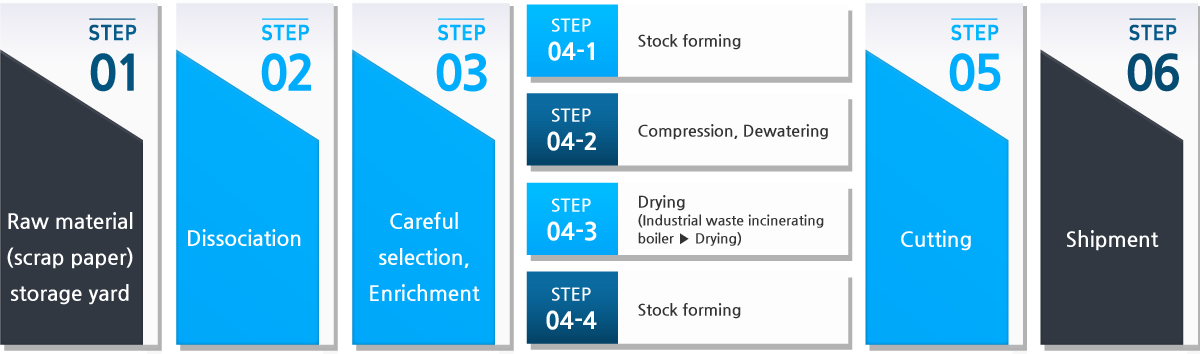

Process Diagram

-

1Import of scrap paper and pulp dissociation

- Scrap papers are selected at a collection place.

- AOCC or KOCC is mixed according to products.

- Water is mixed and then dissociated according to specifications.

-

2Careful selection and enrichment

- Impurities are removed from pulverized materials.

- Long and short fibers are separated.

- Raw materials are dried and highly enriched.

-

3Stock forming and curing

- Stock is formed with raw materials.

- Dewatering is performed with mechanical vacuum.

- Dewatering is performed with roll pressing.

- Drying is done with steam.

-

4Glossy surface

- Surface treatment with high-strength roll pressing (calendar)

-

5Rewinding, packaging

- Rewinding according to specifications

- Packaging (banding, wrapping, and labeling)

-

6Shipment

- Product shipment

Production Process Diagram